What is Sludge Removal and How Can Ecorobotics Help?

There are many types of industrial sludge that come from different facilities.

Industrial sludge is a by-product of residue buildup in tanks or vessels where a liquid is stored or processed. Sludge is seen most commonly in wastewater and sewage treatment centers, refineries, chemical plants, on-site sanitation systems, and paper mills.

Sludge comes in the form of solid, semi-solid, or slurry (a semi-liquid mixture, typically of fine particles); it usually builds up as heavy sludge at the bottom of industrial tanks but can also float to the top when it’s lighter.

Sludge is also referred to as biosolids, but it’s not a direct synonym. Sewage sludge is a solid material that separates during the treatment of municipal wastewater, whereas the EPA refers to biosolids as “treated sewage sludge that meets the EPA pollutant and pathogen requirements for land application and surface disposal.”

Six different categories refer to sludge:

- Primary Sludge: Produced during the municipal wastewater treatment process. The sludge separates after the screen and grit chamber. Sludge at the bottom of a tank is also called primary sludge.

- Secondary/Excess Sludge: Secondary sludge is unused biomass and has to be removed from treatment systems. Excess sludge contains not-hydrolyzable particulate materials and biomass due to metabolisms.

- Tertiary Sludge: Produced through additional wastewater treatment steps after the secondary process.

- Activated Sludge: Activated sludge consists of nutrients and organic matter that come from the biological treatment step. The activated sludge typically comes in the form of flakes.

- Return Activated Sludge: Sludge that flows from the biological aeration basin into the final clarifier. Sludge particles are separated from the water and returned to the aeration basin.

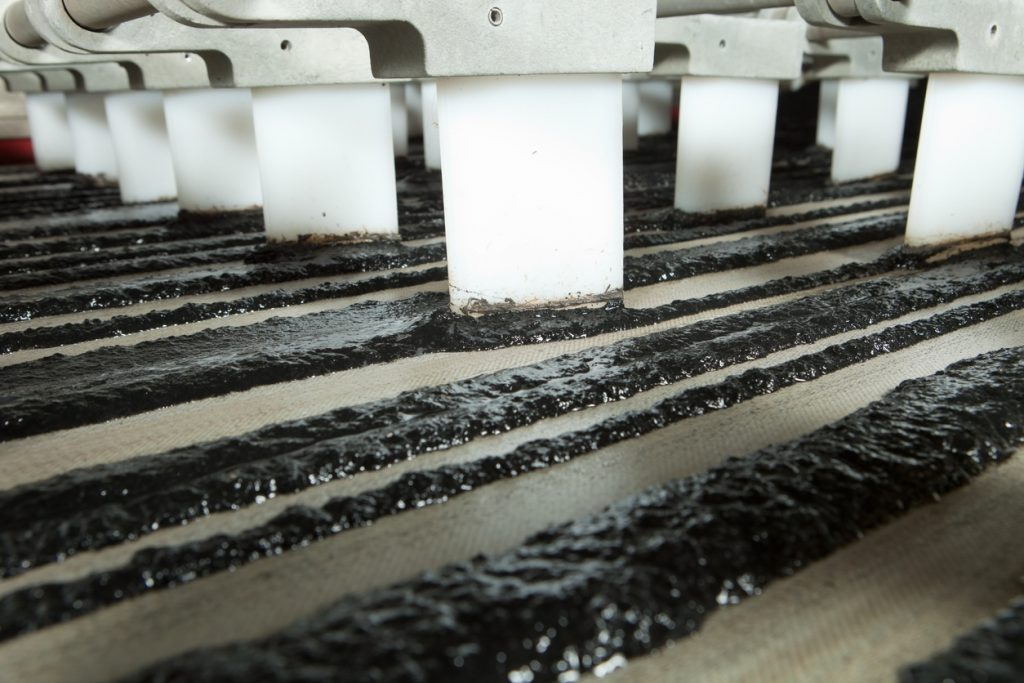

- Digested Sludge: Digested sludge builds up during the anaerobic digestion process. It has a black color and an earthy odor.

What Is in Sludge?

Sludge can have different chemical components. What’s in sludge depends on where it came from, how it’s been stored, what it has been in contact with, and how it’s been treated.

In most cases, sludge contains organic and inorganic materials, trace elements, large concentrations of some plant nutrients, and pathogens.

Sewer sludge specifically contains numerous materials depending on where it’s found and stored. Sewer sludge can include nitrogen, phosphorus, potassium, magnesium, and zinc. Sludge can also contain fecal matter and human waste, which makes it a biohazard.

Sludge as a petroleum byproduct can also contain oil, sand and mineral matter.

Can Sludge Be Used for Anything?

Many companies try to recycle sludge when they can, but it is dependent on the materials in the sludge.

Sludge from industrial tanks and vessels can be used for fertilizer or a source of energy and a replacement for coal.

Sludge is commonly collected and used in the agricultural industry. As a fertilizer, sludge is cheaper with fewer pollutants compared to high-end fertilizer. While it’s not as nutrient-dense, it still works for many farmers.

When it comes to using sludge as a source of heat, most sewage sludge has a high net calorific value of 10–20MJ/Kg and a lower carbon dioxide emission factor when compared to coal, which makes it an excellent replacement.

After the sludge is dried off, it acts as a great soil replacement. Many sludge by-products contain nutrients that help plants and grass grow at an accelerated rate. When sludge is used as soil, it also accelerates reforestation.

Who Needs Sludge Removal?

Any industry that stores, manages, or treats wastewater or liquid needs sludge removal. Containers requiring sludge removal include tanks, sumps, vessels, and trenches, so any industries utilizing these need regular sludge removal.

Common industries that Ecorobotics works with for tank cleaning and sludge removal are chemical and power plants, oil and gas sites, pulp and paper mills, municipalities and sewage treatment facilities, and agriculture.

Why Is Sludge Removal Necessary?

Sludge removal is necessary because it plays a significant factor in the operations of industrial facilities.

Neglecting to implement a sludge removal system can damage your equipment and products, which will often lead to significant expenses.

Sludge that sits for long periods can change the chemical composition of the liquid. Avoiding extended periods of sludge buildup is especially important for the oil and gas industry since the end product must be in pristine condition.

When sludge is removed and the leftover water is treated, it can be recycled and used for other things. In many cases, the sludge can be used as fertilizer, clean water can safely go back into the ecosystem, and incinerated sludge can be used to harness heat and gases.

RELATED ARTICLE: THE MOST COMMON TYPES OF WASTEWATER TREATMENT SYSTEMS

Who Can Help With Sludge Removal?

Sludge removal companies like Ecorobotics can help successfully remove sludge from your production tanks, containers, and vessels with modern technology and practices.

Utilizing robots to assist with your sludge removal will eliminate the inconsistencies of human workers, decrease downtime, and increase profits as well as productivity.

You can learn more about Ecorobotics services on the sludge removal page.